Online 3D printing service

Get instant online quotes on parts in over 80 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.Start A New 3D Printing Quote

STEP | STP | IGES | IGS | SLDPRT | 3DM | SAT | X_T | IPT files and more!

Privacy: All your files are secure with us. Read our privacy policy.What is Stereolithgraphy?

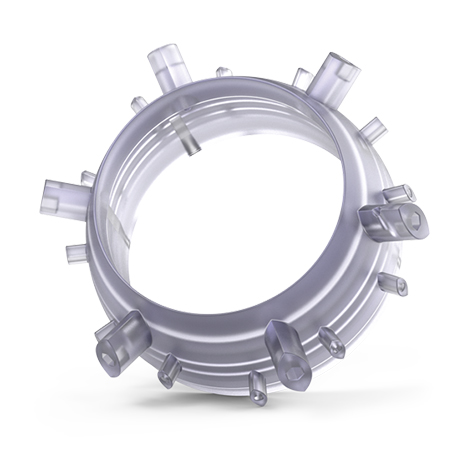

Stereolithography (SLA) is a 3D printing process used to create concept models, cosmetic prototypes, and complex parts with intricate geometries. It's an additive manufacturing technology that forms parts by curing thermoset resin with a UV laser. A wide selection of materials, extremely high feature resolutions, and quality surface finishes are possible with SLA.

SLA 3D printing is primarily used for:

- parts requiring high accuracy and features as small as 0.002 in.

- good surface quality for cosmetic prototypes

- form and fit testing

SLA Design Guidelines and Capabilities

Our basic guidelines for stereolithography include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

*Available for the following materials: ABS-Like White and Gray, ABS-Like Translucent/Clear, and PC-Like Translucent/Clear

SLA Material Options

ABS-Like White (Accura Xtreme White 200)

+ABS-Like Gray (Accura Xtreme Gray)

+ABS-Like Black (Accura 7820)

+ABS-Like Translucent/Clear (WaterShed XC 11122)

+MicroFine™ (Gray and Green)

+PP-Like Translucent White (Somos 9120)

+PC-Like Advanced High Temp (Accura 5530)

+PC-Like Translucent/Clear (Accura 60)

+Ceramic-Like Advanced HighTemp (PerFORM)

+True Silicone

+Compare SLA Material Properties

| Material | Color | Tensile Strength | Tensile Modulus | Elongation |

|---|---|---|---|---|

| ABS-Like White (Accura Xtreme White 200) | White | 7.9 ksi | 479 ksi | 9% |

| ABS-Like Gray (Accura Xtreme Gray) | Gray | 5.8 ksi | 290 ksi | 9% |

| ABS-Like Black (Accura 7820) | Black | 7.0 ksi | 435 ksi | 5% |

| ABS-Like Translucent/Clear (WaterShed XC 11122) | Translucent/Clear | 7.9 ksi | 421 ksi | 6% |

| MicroFine™ (Gray and Green) | Gray or Green | 8.7 ksi | 377 ksi | 8% |

| PP-Like Translucent White (Somos 9120) | Translucent/White | 5.0 ksi | 232 ksi | 25% |

| PC-Like Translucent/Clear (Accura 60) | Translucent/Clear | 10.8 ksi | 508 ksi | 7% |

| PC-Like Advanced High Temp* (Accura 5530) | Translucent/Amber | 6.5 ksi | 566 ksi | 1.5% |

| Ceramic-Like Advanced HighTemp* (PerFORM) | White | 10.9 ksi | 1,523 ksi | 1% |

| True Silicone | Translucent White | 0.711 ksi | n/a | >1,000% |

*Properties listed are based on thermal cure

These figures are approximate and dependent on a number of factors, including but not limited to, machine and process parameters. The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

Surface Finish Options for SLA Parts

| |

| Unfinished | Dots, or standing"nibs," remain evident on the bottom of the part from the support structure remnants. Good for when fast lead times are required or cost is a factor |

| Natural | Supported surfaces are sanded down to eliminate the support nibs. |

| Standard | Supported surfaces are sanded, and the entire part is finely blasted for a consistent look. Note that the layers are still present. |

| Custom | Soft-touch paint, clear part finishing, painting, masking, color matching, decals/graphic, and texture finishes are available. |

Material: ABS-like Translucent/Clear

Finish: Unfinished

Material: MicroFine Gray™

Finish: Unfinished

Material: ABS-like Translucent/Clear

Finish: Standard

Material: MicroFine Gray™

Finish: Standard

Material: ABS-like Translucent/Clear

Finish: Natural

Material: MicroFine Gray™

Finish: Natural

Material: ABS-like Translucent/Clear

Finish: Custom

Material: MicroFine Gray™

Finish: Custom

Metal Plating

Our metal-plating process for SLA coats a ceramic-filled PC-like material (Somos PerFORM) with a nickel that gives parts the look, feel, and strength of metal, but without the weight. The combination of the material’s strength, rigidity, and temperature resistance with nickel plating, takes strength, stiffness, and impact and temperature resistance to a degree previously unattainable in SLA parts.

Microfluidics

Our microfluidic fabrication process is a modified form of high-resolution SLA that uses a clear ABS-like material (WaterShed XC 11122). Parts are resistance to water and humidity, and work well for lens and flow-visualization models.

Our SLA 3D Printers

Our stereolithography machines consists of Vipers, ProJets, and iPros. In high-resolution mode, Vipers and ProJets can make parts with extremely tiny features and crisp details, while in normal-resolution mode, they can build cost-effective parts very quickly.

iPros have extremely large build volumes at 29 in. by 25 in. by 21 in. (736mm by 635mm by 533mm), yet are still able to image highly detailed parts easily.