Online 3D printing service

Get instant online quotes on parts in over 80 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.Start A New 3D Printing Quote

STEP | STP | IGES | IGS | SLDPRT | 3DM | SAT | X_T | IPT files and more!

Privacy: All your files are secure with us. Read our privacy policy.3D Printing Processes

Our online 3D printing service enables you to 3D print your custom part on demand. We offer six 3D printing technologies to transform your 3D files into plastic, metal, and elastomeric parts. With more than 120 3D printers, we have unmatched capacity that reliably delivers parts within days. In addition to a broad material selection, we offer several post-processing options to improve cosmetics or enhance mechanical properties.

FDM 3D Printing Through Protolabs Network

FDM (fused deposition modeling) 3D printing builds parts by heating and extruding thermoplastics layer-by-layer. FDM is a good 3D printing options for strong prototypes and functional parts. Material options include popular thermoplastics like ABS, TPU, PEI, PETG, and more. Get an instant quote for FDM parts within days.

Compare 3D Printing Processes

New to our 3D printing service and not sure which additive technology is right for your 3D design? Compare the capabilities of each process below to see what fits your application's requirements.

| Materials | Max Part Size | Min Feature Size | Tolerances | |

|---|---|---|---|---|

| Metal 3D Printing | Aluminum Stainless Steel (17-4, 316L) Titanium Inconel Cobalt Chrome | 9.6 in. x 9.6 in. x 13.0 in X Line: 31.5 in. x 15.7 in. x 19.7 in. | 0.006 in. | ±0.003 in |

| Stereolithography | ABS Polycarbonate Polypropylene Silicone | 29 in. x 25 in. x 21 in. | 0.0025 in. | ±0.002 in. |

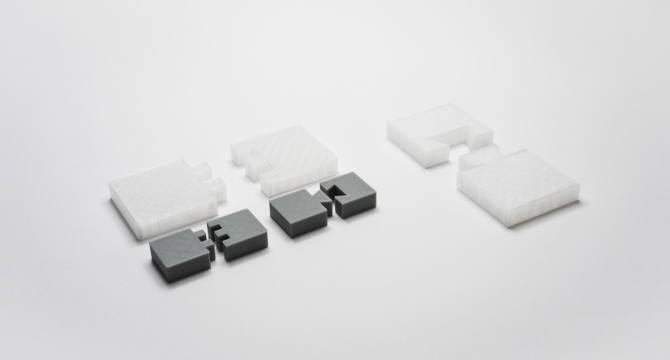

| Selective Laser Sintering | Nylons Polypropylene TPU | 19 in. x 19 in. x 17 in. | 0.030 in. | ±0.010 in. |

| Multi Jet Fusion | Nylons | 11.1 in. x 14.9 in. x 14.9 in. | 0.020 in. | ±0.012 in. |

| PolyJet | Elastomer (30A to 95A) | 19.3 in. x 15.4 in. x 7.9 in. | 0.012 in. | ±0.005 in. |

| Carbon DLS | ABS Polypropylene | 7.4 in. x 4.6 in. x 12.8 in. | 0.020 in. | ±0.010 in. |

"Great service at a fair price and the quality of my parts is fantastic. Keep up the great work.”

3D Printing Toolkit

Get in-depth design advice to optimize 3D-printed parts. Designing with additive manufacturing in mind can accelerate production time and reduce overall cost.

See How Popular Polymer Technologies Stack Up

Two of our most popular 3D printing services, stereolithography (SLA) and selective laser sintering (SLS) offer engineering-grade options for parts. Learn how the two differ and how to pick the right process for your part.

Stereolithography (SLA) and fused deposition modeling (FDM) are two common plastic 3D printing process typically used for rapid prototyping. While both emerged in the 1980s, they use distinctly different ways to make parts, and as a result, have distinct advantages depending on your part requirements.

These two powder bed processes are similar, but there are some differences between the technologies that should be understood before making your manufacturing selection.

Surface Finish Options for 3D Prints

| Unfinished | Dots, or standing "nibs," remain evident on the bottom of the part from the support structure remnants. |

|---|---|

| Natural | Supported surfaces are sanded down to eliminate the support nibs. |

| Standard | Supported surfaces are sanded, and the entire part is finely blasted for a consistent look. Note that the layers are still present. |

| Custom | Soft-touch paint, clear part finishing, painting, masking, color matching, decals/graphic, and texture finishes are available. |

Custom Finishing

Looking to boost the strength, clarity, or appearance of your 3D-printed parts? Choose from microfluidic and micro-resolution materials, metal plating, secondary machining, and custom finishes like painting, clear coating, and decaling.

| Clear Coat | Clear cosmetic finish that can be applied to ABS-Like Translucent/Clear (WaterShed XC 11122) and PC-Like Translucent/Clear (Accura 60) materials. |

| Painting | After smoothing the part with sanding and polishing, parts can be painted with automotive-grade paint. Provide a pantone color with your quote request. We also offer soft-touch painting. |

| Plating | Electroless nickel plating can be used to achieve parts that are similar to cast aluminum or magnesium. |

| Dyeing | Dyeing is another method for adding color to 3D prints. This is faster option with a limited color selection, so is a more cost-effective choice than painting. |

| Decaling | Decaling can be used to add a logo or other graphics to boost cosmetics or function. |

| Polishing | We can polish parts to a mirror-like finish. If this is a requirement, we ask that you provide either a drawing or image that indicates your finish expectations. |

| Heat Treatment | Harden and strengthen metal 3D prints with multiple heat treatment options: NADCAP heat treatment, hot isostatic pressing (HIP), solution annealing, and aging. |

| Machining | Machine metal 3D prints to achieve exceptional surface finish quality or meet tight tolerances. |

Why Choose Us for Custom 3D Printing?

Unmatched Quality

Get design feedback from our experienced engineering team that has helped thousands of customers bring their products to market with quality 3D-printed parts. We will also work with you to determine optimal part orientation based on your application's requirements.

Consultative Quoting

Our industry-leading tolerances and surface finish quality stems from a dedicated process engineering and quality team for each 3D printing technology. We also offer a proprietary material called Microfine™, which can build features as small as 0.0025 in.

Wide Material Selection

Across our six 3D printing technologies, we use a range of commercial-grade thermoset resins, and thermoplastic and metal powders to 3D print parts that are suitable for various part applications and industries. If required for your parts, we offer a variety of post-process options such as heat treating, secondary machining, plating, painting, and dyeing to further enhance mechanical properties and cosmetics.

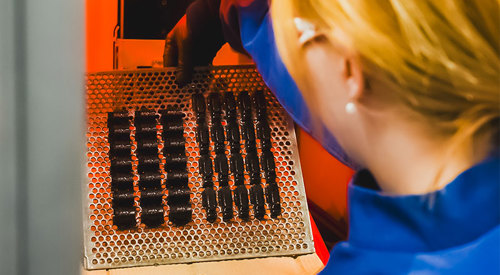

Scale and Production

Our facility is home to more than 120 3D printing machines that produce metal and plastic parts. This means we'll always have capacity when you need parts fast--whether it's a small batch of parts or production level volumes.

What is 3D Printing?

3D printing is a term used to describe a number of additive manufacturing technologies that produce parts one layer at a time from a 3D digital model. Some 3D printing machines will extrude a filament to create a parts, while others use lasers to sinter or cure raw materials like metal or plastic powders and liquid resins. There are a variety of 3D printing technologies that differ in terms of materials, surface finish quality, cost, and quantity to name a few.

Advantages of 3D Printing

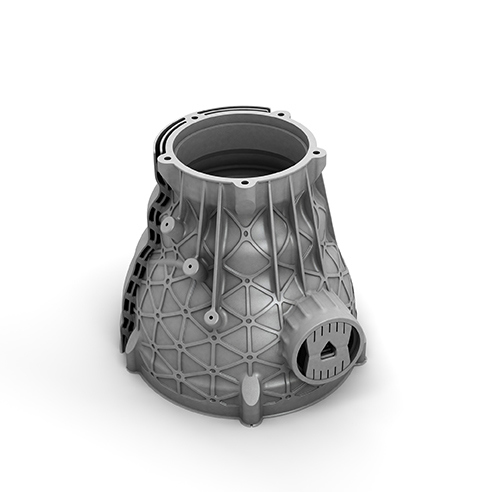

Building parts layer-by-layer brings about many benefits that open up design possibilities that were previously unachievable through traditional processes like injection molding, machining, or casting.

- Complex, organic geometries with limited impact on part cost

- Consolidation of multi-component assembly into a single part

- No upfront tooling costs

- Fast production for parts within 24 hours

- Internal features for advanced heat transfer and flow applications

Common 3D Printing Applications

Additive manufacturing can be leveraged for both rapid prototyping and production in aerospace , medical, automotive, and other large industry sectors. Examples of typical parts, include:

- Form and fit prototypes

- Housings and enclosures

- Medical devices

- Snap fits

- Jigs and fixtures

- Heat exchangers and heat sinks

- Engine components

- Fuel injectors

- Surgical instrumentation